PlasmaTex Inc

Vision

To be a trailblazing leader in the textile industry, catering to the growing demand for environmentally conscious solutions and setting new benchmarks for sustainable practices.

Mission

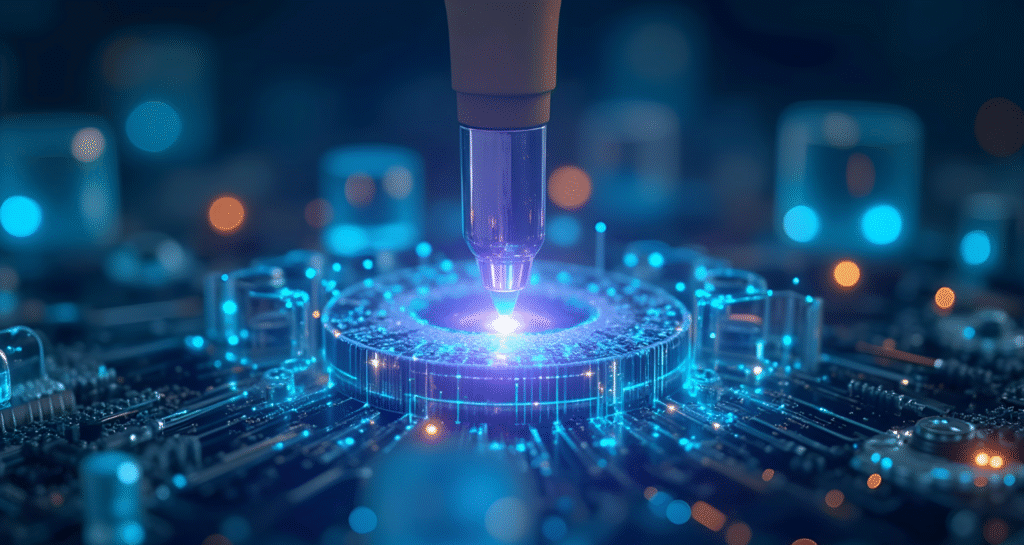

To leverage atmospheric plasma technology to enhance the dyeability of textiles, thereby minimizing wastewater production.

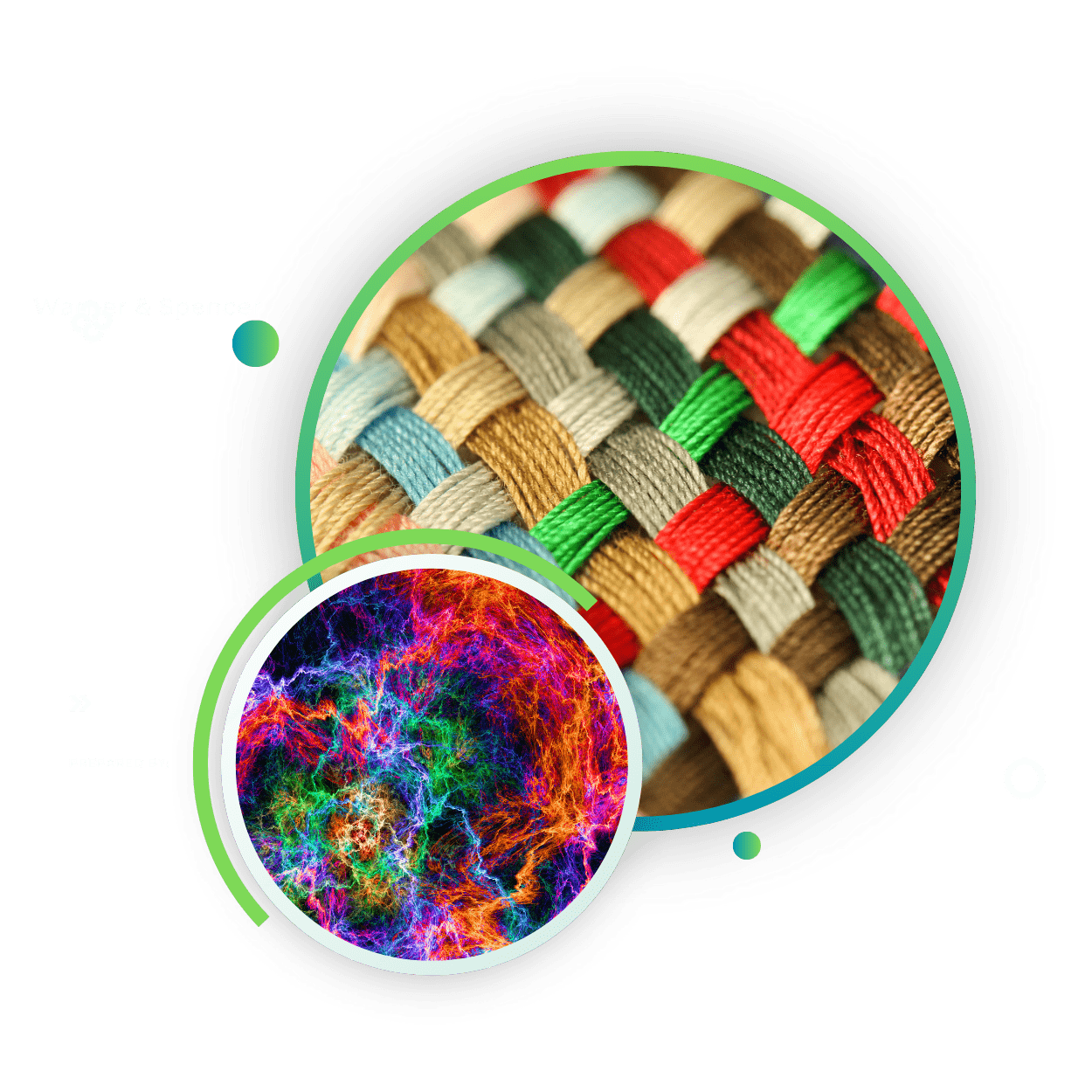

Superior dyeability and color performance

Our atmospheric plasma treatment achieves vibrant, long-lasting color uptake and outstanding dye adhesion across a wide range of textile materials.

Significant water and energy savings

The process dramatically reduces water consumption and dyeing time, helping manufacturers meet sustainability goals while lowering operational costs.

Easy integration with cost-effective equipment

PlasmaTex systems are designed for seamless automation and are more affordable and configurable compared to traditional and competing plasma solutions.

Enhanced durability through nanoscale surface modification

By modifying fibers at the nanoscale, our process strengthens textile durability and surface functionality without altering the bulk fabric properties.

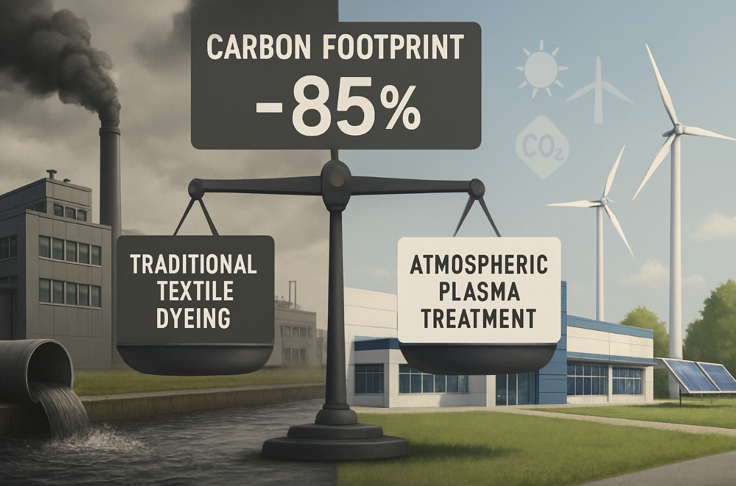

Problems

Residual Dye Contamination

Unsustainable Water Consumption

Chemical Health Hazards

Solutions

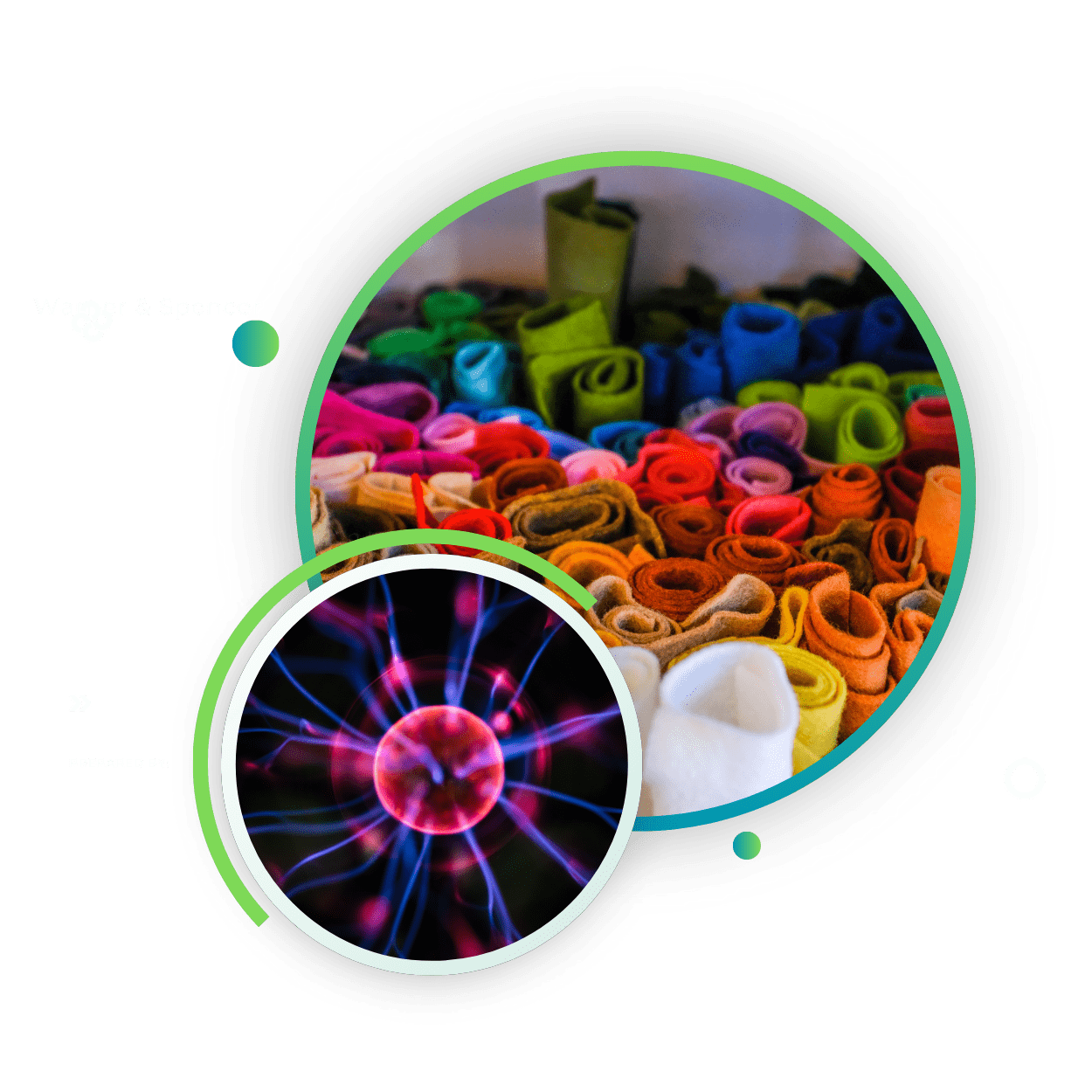

Textile Manufacturing

Plants

Clothing and Fashion

Companies